Product Applications

Note: Examples are written in a Register-Based Advanced Ladder program. See also: Advanced Ladder Logic Programming

Note: Must be signed into the Horner European website to view the sample programs.

Topic Menu

Assembly Line Automation and Data Management

The benefits to automating a production line are endless. A fully automated assembly line does not need people directly involved in the production process doing repetitive tasks. Instead the labor force can be used for system management, supervision and adjustment; and overall time and labor costs are saved. Horner controllers are used in the automation and data management of this Aventics (Emerson) assembly line.

Video Overview

|

Horner APG Automated Production Line |

The video above shows an assembly line in which there are 2 EXL10e controllers which control a total of 20 digital IO nodes and about 1000 Aventics (Emerson) pneumatic valve CANOpen nodes, including some Smartrail nodes. In this assembly line there’s also an XL4 controller that manages a thermal printer, and an NX controller on the last station which controls a linear axis by RS232 connection and performs quality tests on each valve assembled in the line. A second XL4 does MES and keeps track of collected data.

Return to the Top: Product Applications

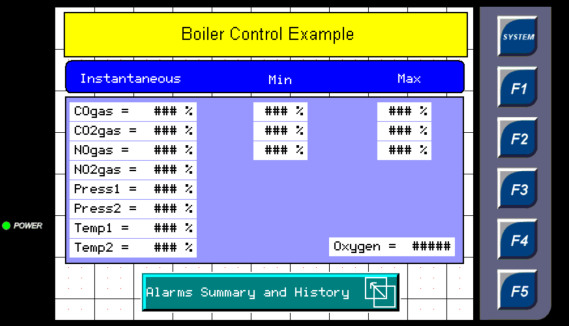

Boiler Control

Properly handled combustion boilers can be a very efficient source of energy. The task however can be quite complicated, when taking possible anomalies into account and of course the impact on our environment. That’s why the proper analysis of the exhaust gases and then control of the burning cycle can bring not only cost savings but also safety and environment friendly results.

In a system of six industrial boilers, each boiler can have up to 8 analog inputs, one analog output and some digital I/O points. All data needs to be scaled and should have min/max alarms. Most of the data measured needs to be calculated in different engineering units, depending on the fuel used in the burner. The data then needs to be logged and stored for future reference and analysis.

Based on the system requirements, Horner has developed a solution consisting of a main controller, together with multiple SmartMod I/O modules (Modbus RTU), with one module per boiler. The controller uses a microSD card for all the necessary datalogging, and because of the embedded Ethernet port, the entire application can be monitored and controlled via a Web Server or Envision RV.

A Horner solution was chosen because of its datalogger and remote access options. Also the working conditions (wide temp. range, dust and electrical noise) were harsh, and the maintenance team needed real-time data to determine the level of pollution (hence colorful, good quality screen).

The benefits for the plant manager are quite obvious. Proper oxygen content control optimizes the air/fuel ratio which equals energy savings. The process itself becomes safer, because whenever an anomaly is detected, the burning cycle can be corrected. To sum up: correct combustion means money savings and safer and cleaner plants.

Implementation

During the first stage of implementation, the OCS was used as an exhaust gases analyzer. Multiple probes connected to each SmartMod I/O measured levels of gases such CO, CO2 or NO, as well as the pressure and temperature (up to 8 signals). The controller was scaling, calculating and storing the values on the Flash memory. This data was crucial to determine whether the process was environmentally safe. The second phase was embedding the control algorithm into the burner working cycle and dosing the oxygen input.

Cscape Program Example

Click here for the program website.

The Cscape configuration file consists of:

-

Hardware configuration of a controller and a SmartMod remote I/O unit.

-

Scaling procedures

-

Finding Min/Max Values

-

Control procedure

-

Handling Alarms

-

Datalog configuration

-

Application Screens

Return to the Top: Product Applications

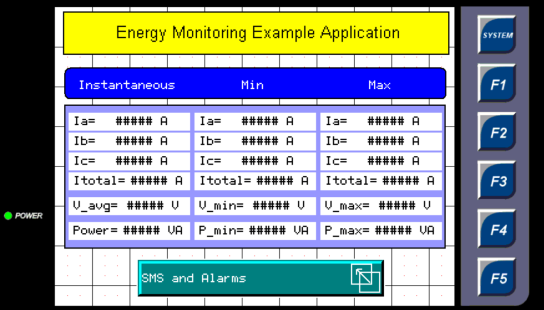

Energy Monitoring

To effectively reduce energy costs they need to be monitored, analyzed and then efficiently controlled. Horner devices working with remote I/O and sensors, offer you the ideal solution for your energy monitoring needs.

Horner offers an easy to install solution for you energy monitoring needs, by monitoring and data-logging your energy consumption.

Using a Horner all-in-one controller, all the standard values as well as more in-depth Current/Voltage/Power measurements can be logged and monitored.

Typical measurements which can be monitored:

-

Instantaneous Current and Voltage for each phase

-

Voltage Average (Instantaneous and Min/Max)

-

Current Total (Instantaneous and Min/Max)

-

Power (Instantaneous and Min/Max)

-

Power Factor

-

Frequency

-

Power Used Today (kWh, numeric)

-

Power Used This Month (kWh, numeric)

-

Month Peak (kW)

Horner I/O Usage and Working with Sensors

See also:SmartStix and SmartBlock Modules

The SmartBlockPower and Energy Monitor module (HE579ACM300) offers the same level of in-depth measurements together with the freedom of using any Horner controller with a CAN Network. Select an All-in-One controller with the preferable screen size, connect the SmartBlock via the CAN network and customize the application by using the free Cscape programming package.

It is easy to design alarms, display a graph or configure custom SMS messages which can be triggered by a specific event. CAN network gives the opportunity to connect more than one SmartBlock and in effect to control multiple circuits from a single controller.

This is an alternative solution is for engineers who’d still like to design their own system with the controller of their choice, but do not need all the information that the SmartMon or SmartBlock ACMN provide. This solution allows them to keep their measurements and program simple.

There are third-party components (transducers) such as those available from LEM, Socomec, ZURCK, Circuitor, SSET (and others) that can measure Current, Voltage or Power for a single or three phase systems. Transducers then can pass that information via standard analogue signal (like LEM) or (in some cases) Modbus Serial connection (like SSET) to even the most compact Horner controllers like the XLE.

View, Monitor, and Control

See WebMI Manual

Access the Energy application from a user-friendly interface with WebMI. With Horner WebMI, the user can monitor and control plant data from a cell phone or tablet, allowing remote interaction. The user can browse through the screens, modify all changeable values, use function keys – no restrictions.

Published directly from the OCS Controller, WebMI allows the same or unique Web pages to be monitored and controlled from your computer, tablet or other mobile device.

Click here to learn more about WebMI.

Horner Controller Useful Features

-

Datalogging – To keep track of all operations and store the measured data (all saved on 2GB MicroSD card and easily accessible from the PC).

-

Alarm Messaging – Descriptive messages that will pop-up on the OCS display like ‘Current Overload’. All alarm messages can be personalized. See Alarm Configuration (Graphical) for Canvas

-

SMS Communications Maintenance – Fully configurable text message that can be sent in case of emergency or reporting.

-

Advanced Math Instructions – To program and calculate complex energy factors. See Math - Advanced in Advanced Ladder

Cscape Program Example

Click here for the program website.

The file consists of:

-

Parameter Overview screen (Screen 1)

-

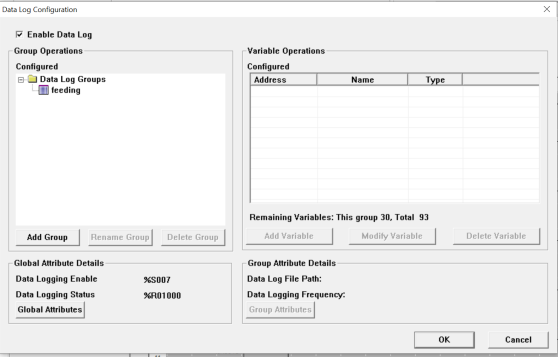

Datalog Configuration (Menu Program -> Datalog Configuration…)

-

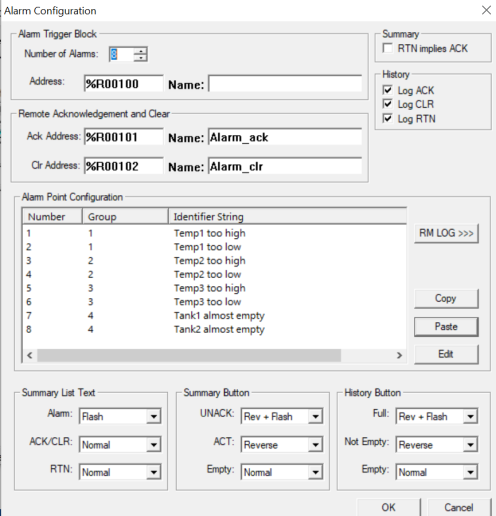

Alarm messages configuration (Screen Editor -> Menu Config -> Alarm)

-

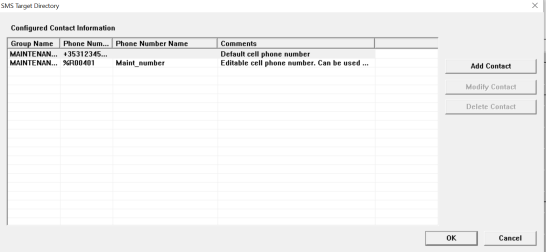

SMS configuration (Menu Program -> Messaging -> SMS)

-

Alarm and SMS screen (Screen 2)

-

Code for calculating energy parameters (Logic Modules -> Main Loop Modules -> Main)

-

Code for handling SMS (Logic Modules -> Main Loop Modules -> SMS)

-

Code for handling Alarms (Logic Modules -> Main Loop Modules -> Alarms)

Return to the Top: Product Applications

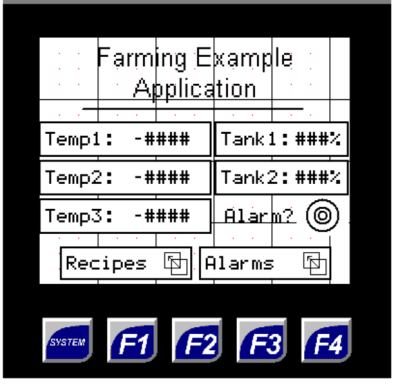

Farming

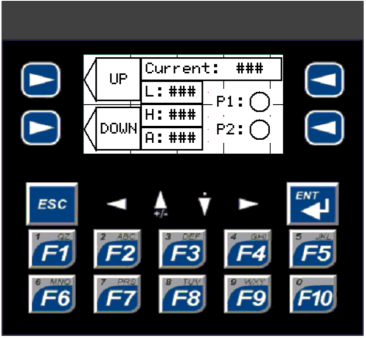

This application is dedicated to a large volume farmer, whose concern is to make his feeding system following a specified feeding program. He also required the system to have easy editability with alarm and logging functionality.

The farmer understands that the key to the successful growth of his stock lies in the correct feeding procedure. Based on his experience he creates the feeding table that shows exactly how much feed should be given to attain the optimum weight and how their feed blend should be changing during their life cycle.

Horner has a solution for many requirements, budgets and programming levels. As needs grow, these systems can grow as well and be easily expanded across a plant, office, or any other facility.

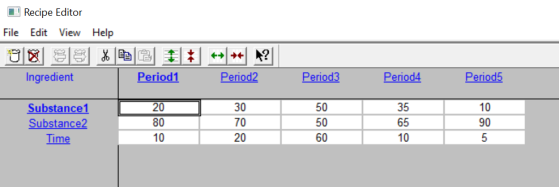

Normally a farmer would have a manual system that is prone to error and labor intensive. Fortunately new technology has been developed which can simplify the whole process and save time and effort. Multiple ‘recipes’ can be simply stored in internal memory and precisely followed every day, with the possibility of editing them at any time. See Recipe Editor Configuration for Canvas

Example:

Controller Data Logging

The unit would also keep track of all operations, temperatures, alarms, and convey the feed to the point of feeding etc. All process data can be logged on the removable flash memory. See Datalogging

Alarm Messaging

Any event (radical changes in temperature, drop in feed storage level, etc.) can be associated with a descriptive message that will pop-up on the OCS display like ‘Tank 1 almost empty’. All alarm messages can be personalized to meet the needs of any customer. See: Alarm Configuration (Graphical) for Canvas

SMS Maintenance

All Alarm messages can be sent directly to your smart phone. Multiple phone numbers can be preconfigured or made dynamic, so you can change the recipients from the level of your OCS screen.

There is also the advantage of monitoring the bulk feed storage level and reordering (via SMS) before it runs out. See SMS Communications

Sample Hardware Configuration

See also: The Controller Overview

See also: Hardware Configuration

In order for a farmer to monitor 3 temperature levels, 2 storage tank levels and status of an emergency button, and that he will need the following:

-

10 feeding station valves

-

2 conveyor belts

-

2 ventilation fans

Which requires 1 Digital Input, 14 Digital Outputs, 2 Analog Inputs, and 3 Temp Inputs.

Solution A - XL series OCS, built-in I/O and remote temperature module

-

XL Series OCS

-

GSM modem for SMS messaging.

-

Smart Mod THM100 or RTD100 (depending on the temperature sensors)

Solution B - XL series OCS and SmartMod I/O

-

Horner OCS, built-in I/O and Remote Temperature Module

-

XL Series (Model 2)

-

GSM Modem for SMS messaging

-

SmartMod THM100 or RTD100 (depending on the temperature sensors)

-

SmartMod ADC107 or ADC120 (voltage/current analog input)

-

4 x SmartMode DIQ512 for Digital I/O

Solution C - Most cost-effective controller with remote I/O

-

XLE model 2

-

GSM modem for SMS messaging

-

SmartMod THM100 or RTD100 (depending on the temperature sensors)

-

SmartMod ADC107 or ADC120 (voltage/current analog input)

-

SmartMod DIQ512 for Digital Outputs

-

SmartStix DQM602 for 16 Relay Outputs

Cscape Program Example

Click here for the program website.

The file consists of:

-

Recipes configuration, see Recipe Editor Configuration for Canvas

-

Datalog Configuration, see Datalogging

-

Alarm messages configuration, see Alarm Configuration (Graphical) for Canvas

-

SMS configuration, See SMS Communications

Return to the Top: Product Applications

Water Flow Control

Water flow control application shows along with the other applications the wide range that Horner units cater to. This fun application is being controlled by an XL7 with Modbus communications to the pump drives and SmartRail I/O for the digital and analog control.

This application controls the flow of water which creates an artificial surf wave. The application is rather complex as it controls water level in a huge tank by controlling the pumps. The water outlet is controlled by four hatches which establish the wave, the water must be pumped up to a preset level before the hatches open individually to specific positions in order to establish the wave. When it is established, the water flow must be reduced to maintain the wave in the right profile.

Every now and then, they generate a huge tsunami wave by closing all hatches, filling the tank to it’s maximum before opening all hatches fully. This generates a huge wave that runs around the whole canal before a new surf wave is established again.

Return to the Top: Product Applications

Bakery Application

Bakeries and other food processing industries are being improved with automation solutions. This bakery application has multiple OCS units installed. The central EXL10 unit is responsible for handling recipes (about 200), overview of the process and communication with the compact XLEe units. The EXL10 screen size should be enough to give the user a SCADA like experience and precisely monitor every aspect of the process. Communication between the two is handled over peer-to-peer CsCAN network which gives the benefit of fast and easily accessible information.

The ethernet port on the main EXL10 OCS gives remote access not only for the user’s benefit, but also for the system integrator, who can support his application remotely and much faster. Such support includes debugging and re-programming over Cscape, but also (together with WebMI) remote access to all diagrams and data fields displayed on any of the OCS screens. As for the recipes, WebMI guarantees easy Import and Export over Ethernet without any interference with the process. Any recipe update is handled seamlessly.

Once the proper recipe has been loaded, all necessary information is transferred over the CsCAN network to the multiple XLEe devices. They are responsible for the proper dosage of water, flour and other ingredients as well as for the water temperature. All this is achieved by using a remote SmartStix I/O and both XLEe communication ports. One of them is connected with a weight controller over Modbus RTU, the other is exchanging parameters with the water system via custom RS232 protocol. Both communication ports are working independently, all together with the CsCAN messages being exchanged between the central EXL10 unit.

Cscape Program Example

Click here for the program website.

The file consists of:

-

Hardware configuration, see Hardware Configuration and SmartStix and SmartBlock Modules

-

CsCAN data exchange code for both units, see Networking and Communications

-

Recipe handler for EXl10, see Recipe Editor Configuration for Canvas

-

Sample protocol configuration for XLEe, see Protocol Configuration

Return to the Top: Product Applications

Quality Control and Testing for Industry

Quality control and minimizing defects in products is of paramount importance in modern industry. Horner EXL10 controllers are used in this pneumatic valve testing machine to ensure consistent quality of products and to find products with defects. This system also makes use of data logging and MES. There are many advantages to using Horner controllers to perform quality control for automated systems. All defects in products are detected, due to the ability to test every product if needed (rather than a sample from a batch). Horner controllers also allow data to be collected about all defects and errors, which can be analyzed to minimize errors and save both time and money in the future.

Application Overview

The machine consists of a rotating table driven by a gear motor. There is a loading/unloading station in which the following series of operations occur:

-

The machine operator, protected by a security gate and a safety curtain to avoid injury, unloads the tested valves from the set of gauges and loads the valves to be tested.

-

The start cycle button is pressed, causing the rotating table to re-position the valves to a 2nd position. The operator repeats the operation detailed in Step 1 in this new position and the valves are filled with pressurized air at a preset pressure.

-

Following this, the valves are brought to a 3rd position in which no operation is performed, followed by another position and so forth until the valves get to the final station, in which the air pressure is measured again with pressure gauges. If the initial pressure value read in Step 2 minus the new read value is within the acceptable range, then the valve passes the testing and can be moved on. If not, the valve goes into a check area where another operator determines if it has been assembled properly and fixes the problem.

Return to the Top: Product Applications

Water Treatment Application

When it comes to automation solutions for water treatment applications, there are plenty of options. From a standalone station supervising a single pump to a more complicated system of multiple stations with a two-way communication. This example features a double-pump station, which is being constantly polled for data from the centralized SCADA system.

Horner Controller

The controller we are going to consider for this task will be the XLEe, Horner’s most compact and most cost-effective device on the market (also recommended is the touch screen version: XLTe). In a case like this, with a pump site in a remote location, there’s no need for a device with a bigger screen. This time the screen will be used entirely for maintenance and debugging. The rest of the monitoring should be fully covered by the SCADA system.

Application Overview

The application itself can be as advanced as the programmer wants it to be, but there are few key procedures that our application should have: Manual/Auto mode, Alarm Handling, Communication (for example via GPRS) and local Data Logging to reduce polling rates of the SCADA.

The pump station in auto mode would be responsible for maintaining the level (of water, sewage, etc.) between the set low/high levels. The program should also alternate the workload, so the usage for both pumps is close to equal. If the emergency level is reached, both pumps should immediately be switched on. Manual mode is most often used for maintenance and allows the operation of both pumps.

Communication

Reporting to the main station could be done in several different ways, for example via GPRS modem, radio modem or Ethernet connection. Because of the remote location of our site the first two options seem to be the most appropriate. The central SCADA system is usually responsible for dozens of similar sites so the connection speed has to be taken into account.

Cscape Program Example

Click here for the program website.

The file consists of:

-

Datalog Configuration, see Datalogging

-

Alarm messages configuration, see Alarm Configuration (Graphical) for Canvas

-

GPRS configuration, see GPRS (General Packet Radio Service)

-

Code for auto mode

-

Code for handling Communication

-

Code for handling Alarms

Return to the Top: Product Applications